The most frequent term might well be “di p package in the world of electronics. But what does this mean? In this post, we will roll our sleeves and understand it to the best of what is humanly possible.

What Is A Dip Package?

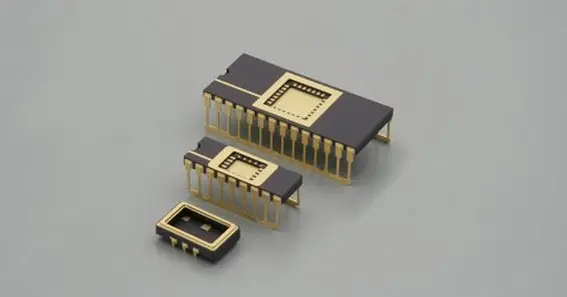

Dual In-line Package (DIP) – A DIP, or a “dip package”, is an integrated circuit housing 2 rows of pins running parallel to each other across the device. Now, picture that small rectangular block with 2 rows of pegs sticking out the sides — a dip package.

Also Read : Spooky Halloween Words That Start With Y

Why Are Dip Packages Used?

- Dip package versatility: To be housed in dip packages, the electronic components can vary from microcontrollers to memory chips.

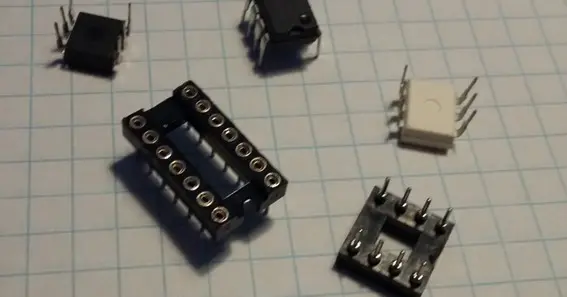

- They are easy to use – you can plug them right into sockets on a printed circuit board (PCB), so they’re good for prototyping and testing.

Dip packages are old and have been seen in a lot of previous-generation electronics, hence the historical significance tag. While the use of dip packages has decreased with new packaging options, they are still widely used in many applications due to their simplicity and reliability.

Also Read : What Is Crossing The Threshold – A Quick Guide

Types Of Dip Packages

Variants of dip packages

- DIP (dual inline package) in Through-Hole Packages: These will have leads/pins that go through holes on the PCB for soldering.

- Surface Mount Dip Packages: These are bound to the surface of your board directly without any holes.

Advantages And Disadvantages

Advantages:

- Reliability: Dip packages tend to be a lot more robust when it comes to handling, and far less likely to break than SMT devices.

- Availability: Thousands are made every day from many suppliers. This means in the unlikely event a component breaks, replacement of it is as simple as getting on another one with zero downtime!

Disadvantages:

- Spatial Overhead: Dip packages can be bulkier than newer, smaller surface-mounting package (SMD) options.

- Density: due to their size, dip packages have fewer pins or features than the more modern designs.

Conclusion

Everyone who wants to deal with electronics must understand what are dip packages (DIPs). But whether you are a hobbyist or doing projects professionally, it is useful to have some foundational knowledge so that you can choose the right components for your projects. Dip packages continue to serve as a strong complement in the electronics industry, ensuring reliability and ease of use.

When you come across a dip package next time, just remember it’s not merely a row of pins — it’s a pocket full of hearts(computer) for whom your device takes shape!

FAQ

What Are Dip Packages In Electronics?

In electronics, a DIP or Dual In-line Package is packaging for an integrated circuit that consists of two rows (dual) of flat contacts extending from a rectangular body. Featuring a pair of rows emanating from its sides, it is designed with insertion into circuit boards in mind.

What Are the Types Of Dip Packages?

DIP packages are mainly of two types: Through-Hole DIPs, which have pins that extend through holes in the circuit board for soldering, and Surface Mount DIPs, these components mount directly onto the surface of a printed circuit board( PCB).

But Aren’t Dip Packages Still Created Even Now With All These New Techniques?

Dip packages are still in use primarily due to their longer history, ruggedness, as well as ease of replacement. It is very popular where high reliability is required and preferred for prototypes or testing of any equipment.

Dip Packages Are Best For What Benefits?

Dip packages are primarily designed for mounting only electronic components, are easy to handle in the installation process, and are resistant to mechanical stress during operation.

What Are The Cons Of Dip Packages?

While versatile, dip packages remain larger than newer packaging styles such as surface mount devices (SMDs), making them impractical for high-density applications. They also take up more physical board space and might not provide as many I/O perimeters or features compared to current options.